Safety line Z100

System for control of technologies nearest to nuclear reaction

The system SandRA Z100 is intended for the realization of the control and monitoring functions classified in the highest safety categories. Completion of this line of process stations in the control system SandRA family enables us to control the complete operation of a nuclear power plant, including the most important safety systems.

Qualification

Our control systems rank among the equipment vital for nuclear safety, they are qualified for both ordinary and extraordinary operations, tests, and occurrence of emergency conditions. The systems can absorb changes in the environment related to these defects. All is performed according to the qualification program and outputs from the qualification represent one of the inputs for licensing process.

Licensing

We are a part of the approval process in the parts related to safety systems and the systems related to nuclear safety that is based on the Atomic Energy Act. In the licensing process, there is evaluated realization and safety documentation from the point of view of relevant requirements for assuring nuclear safety. The result is represented by a binding statement of the State Nuclear Safety Authority on the mentioned safety documentation and permission for putting it into operation.

Certification abroad

Process stations

Process stations are intended for direct control of technologies in real time. They execute assigned controlling and regulation algorithms, evaluate measured input values, and control the regulated technology through their outputs. They communicate with a higher level of control system through the data network, with each other, and also with the stations of remote inputs and outputs, SMART sensors, and actuators.

SandRA Z100 line

These stations are intended for the realization of control and monitoring functions classified in the highest safety categories, namely for the field of nuclear power engineering. This corresponds to the general concept of the process station's solution including software equipment focusing on maximum reliability and ensuring a high level of system self diagnostics and diagnostics of connected circuits.

Z100 line includes three basic types of stations:

Modular stations

intended for the general part of safety functions. Properties of a particular control station (e.g. number of the input and output signals, their type and scope, types and numbers of communication channels, supply voltage, computing capacity, etc.) depend on the configuration of the station – and these on a type of built-in modules applied. These properties are, to a large extent, possible to be changed and developed, also through the development of new types of modules. Input and output modules process mainly standard signals (0-20 mA, 24 VDC, etc.). Therefore these stations can be also applied in safety applications outside nuclear power engineering.

Special stations

solve safety functions requiring specific hardware. Properties of a particular control station are given by its type. Each station is at maximum adjusted to controlled technology. An example is represented by stations (subsystems) for control of drives controlling regulation rods in nuclear reactors, or stations evaluating the position of these rods.

Special modules

This group includes displayers, controlling elements, and remote I/O modules meeting the high requirements for safety and reliability, the same as other components of the Z100 line. These elements are usually applied in the unit or emergency control rooms in nuclear power plants.

System software

The software of the SandRA Z100 platform is based on a long-term experience that ZAT has obtained from the projects focusing on the design and implementation of digital control systems in nuclear power plants.

The software for these projects has been developed using the company sources and well proved implemented testing methods. The process of developing SandRA Z100 platform software is based on an approach applied in these projects and it is according to the requirements of standards IEC 60880, IEC 62138, and IEC 61508.

The architecture and simplicity of this software make its understanding and testing easier.

Visualization and control rooms

SandRA Horus is HMI (human-machine interface) that has been entirely designed with regard to an application in the projects realized with increased requirements for safety and reliability. This HMI includes various versions of operators´ panels that are modified according to customers´ specifications and enable us, under defined conditions, to give commands for safety functions. It also contains a reliable archive that is ready to save all important data from the technology as well as the control system. Last but not least, it also includes a universal diagnostic system providing all comfort for a diagnostic summary on the state of the technology and control system.

All this is within the operating system Windows or Linux. It means that SandRA Horus is ready to complete a line of the hardware HMI (such as mosaics, displayers, and switches) that SandRA Horus exceeds thanks to users´ friendliness and comfort.

Possibilities to use the SandRA platform safety line

The safe, innovative and flexible control system in accordance with necessary standards and legislation. It enables us to control the complete operation of the primary part and to realize the functions classified in the highest safety categories A, B.

The safe, innovative and flexible control system in accordance with necessary standards and legislation. It enables us to control the complete operation of the primary part and to realize the functions classified in the highest safety categories A, B.

Nuclear reactors

The system, verified through operations in large nuclear reactors, can control elementary protective functions. It cooperates with the industrial line Z200 in case of realization of the functions in lower safety categories.

The system, verified through operations in large nuclear reactors, can control elementary protective functions. It cooperates with the industrial line Z200 in case of realization of the functions in lower safety categories.

Experimental reactors

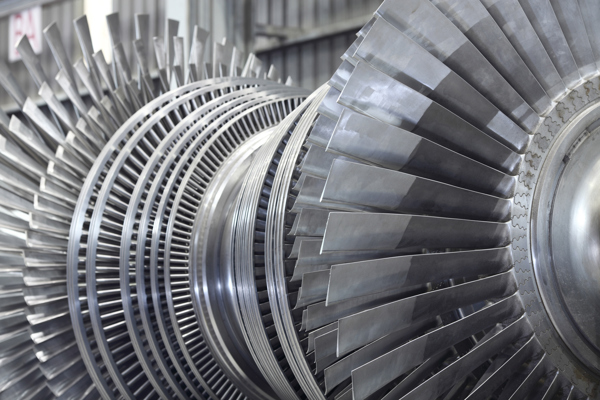

The solutions meeting strict qualification criteria thanks to the setup processes and selected tools. The safety integrity conditions have been fulfilled up to the SIL3 level for the systems related to the safety of the turbine protection system.

The solutions meeting strict qualification criteria thanks to the setup processes and selected tools. The safety integrity conditions have been fulfilled up to the SIL3 level for the systems related to the safety of the turbine protection system.