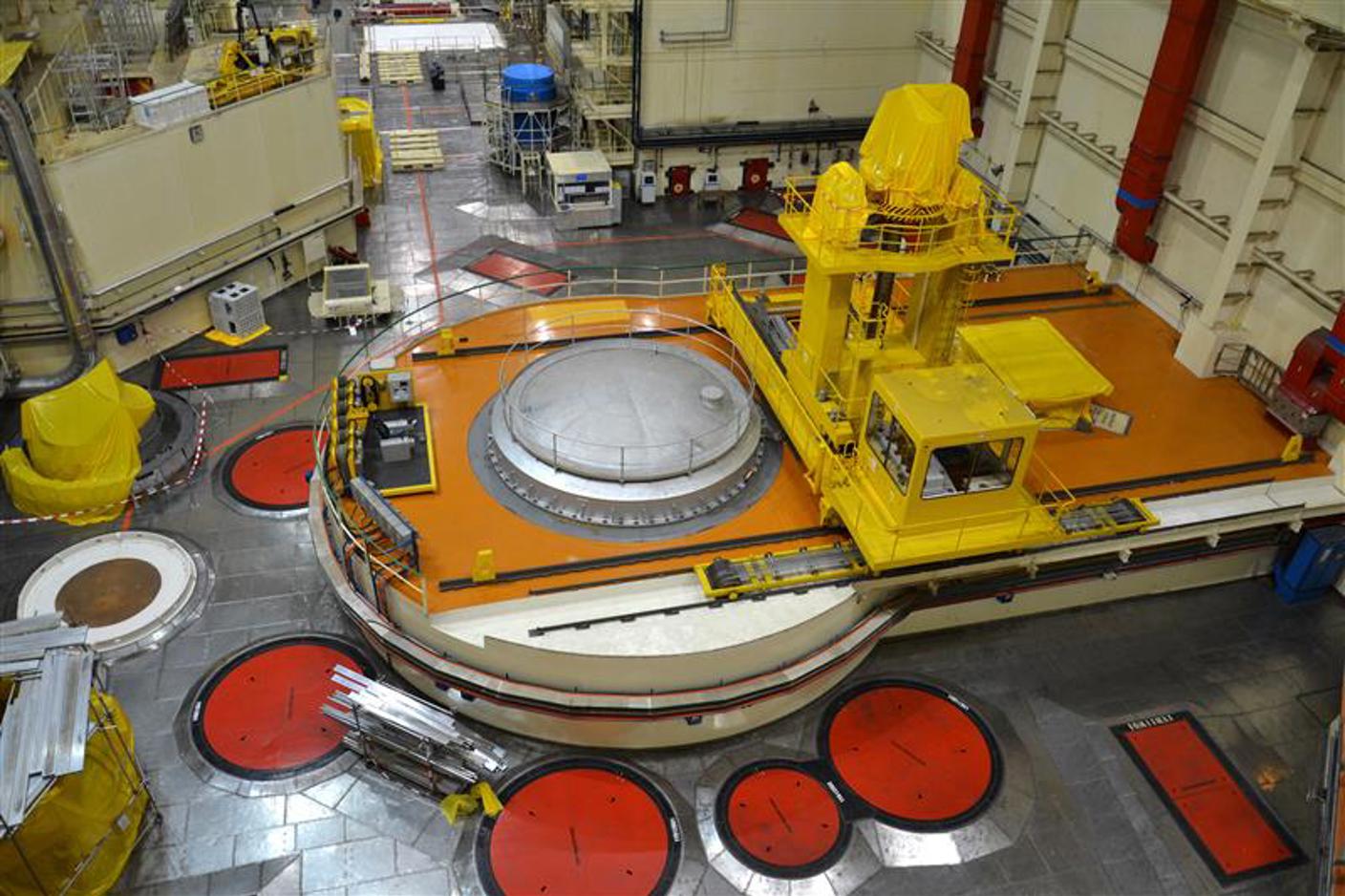

Solution for primary circuit of NPP

More than 47 years of experience in supplying control and monitoring systems for both large and small nuclear reactors, as well as related nuclear technologies, including services. We are an established player in the field of nuclear technology control system deliveries, both domestically and internationally.

We meet the legislative requirements of nuclear safety authorities in the Czech Republic and six other countries worldwide.

-

Reactor Rod Control System (externí odkaz)

-

Reactor Control System (externí odkaz)

-

Regulation Trip Breaker (externí odkaz)

-

Reactor Vessel Level Instrumentation System (externí odkaz)

-

In-Core Measurement System (externí odkaz)

-

Primary Circuit Technology Control (externí odkaz)

-

Post-Accident Monitoring System (externí odkaz)

Reactor Rod Control System

We offer the delivery of a new or modernized Reactor Rod Control System (RRCS). The system complies with current legislative requirements in terms of nuclear safety, operational reliability, user comfort, and maintenance. At the same time, it meets strict qualification standards.

The new, modernized RRCS is essential for ensuring nuclear safety in new or upgraded nuclear units. It is designed on the SandRA platform using the modern digital control and information system ZAT SandRA Z100 and the ZAT Horus HMI system, and it performs functions in categories B and C according to ČSN EN 61226. The system is communicatively linked to the Unit Control and Information System (UCIS).

Key features and benefits include more precise evaluation of rod position for rotary drives (higher accuracy for stepper drives depends on the position sensor used). It also includes test modes for reactor startup procedures and supports reduced system maintenance time during planned outages. The projected lifespan of up to thirty years, supported by the SandRA control system lifecycle, includes extensive diagnostics of the mechanical condition of the drive, rod cluster, and fuel assembly.

The final stage is supplied according to the type of control mechanism, either for linear stepper drives of types LKP-M, LKP-M/3 up to LKP-M/4, ШЭМ-3, or for synchronous rotary drives of types RD42, РД42-4Р.

The system provides power supply and position evaluation from sensors of types UP-1 to UP-3, UP-4, ДПШ for linear stepper drives, and from sensors of types LD-1, ИДП for synchronous rotary drives.

The Reactor Rod Control System, supplied by ZAT a.s., currently ensures reliable and safe nuclear fission in VVER440/1000/1200-type reactors. At the same time, we are ready to adapt the system based on requirements for other types of control mechanisms and for other types of large and small reactors.

Reactor Control System

The Reactor Control System (RCS) is designed for the automatic regulation of the reactor's neutron power and steam pressure in the main steam header. The system is implemented on the SandRA Z100 platform.

We offer the delivery of both new and modernized pressurized water reactor power control systems, meeting current legislative requirements in terms of nuclear safety, operational reliability, and operator comfort. The new power control system is based on the modern digital control system ZAT SandRA Z100 and performs functions in category B according to ČSN EN 61226. It is communicatively linked to the Unit Control and Information System (UCIS).

The system regulates reactor power according to the turbogenerator output and stabilizes the set level of neutron power. It supports both base-load operation and load-following without requiring reactor shutdown or pressure relief.

The functional capabilities of the system, which operates continuously during normal conditions, are constantly monitored through the measurement of relevant parameters.

Exceeding preset parameter limits is signaled. An automated operational diagnostics system is used to monitor equipment status during operation. Data collection and transfer to the company network for archiving and further evaluation are carried out using modern computer technologies.

The Reactor Control System supplied by ZAT a.s. currently ensures reliable and safe power regulation for VVER440-type reactors. At the same time, we are ready to adapt the system for other power levels and types of both large and small reactors based on customer requirements.

Regulation Trip Breaker

The purpose of the Regulation Trip Breaker (RTB) is the rapid disconnection of the power supply intended for the reactor control mechanisms.

The RTB system is divided into two identical sets connected in series to ensure higher reliability. These sets are located in separate rooms and cannot be taken out of service simultaneously.

If either of the RTB sets is activated, it safely disconnects the power supply to the control mechanisms, resulting in a rapid reactor shutdown.

The system operates based on commands from the associated protection systems and commands from the operator in the unit and emergency control rooms. Built-in user functions allow easy testing of the power switches’ on/off operations and collection of diagnostic data. Information about the status of main functions, fault detection, and signaling of faults within the RTB system is also displayed.

It is communicatively connected to the Unit Control and Information System (UCIS).

It performs the highest safety function, category A, according to ČSN EN 61226 and is developed using ZAT-RA technical equipment.

The Regulation Trip Breaker (RTB) system, supplied by ZAT a.s., currently ensures reliable and safe power regulation for VVER440-type reactors. At the same time, we are ready to adapt the system for other power levels and reactor types based on customer requirements.

Reactor Vessel Level Instrumentation System

The system is designed to measure the water level in the reactor vessel, monitoring the level inside the reactor using level measurement assemblies that meet all specified safety design measures and requirements for geometry and construction. The level measurement system uses KNI-LM assemblies designed by ŠKODA JS a.s. These assemblies are based on the neutron measurement method KNI, which has been used inside reactors to date. The measured level is transmitted to the Post-Accident Monitoring System (PAMS).

Redundant level measurement assemblies are used, employing both heated and unheated thermocouples as sensors. These thermocouples maintain good thermal contact with the inner surface of the common tube. The unheated thermocouples serve as reference sensors, making the system independent of the medium temperature.

The system performs safety functions in category B according to ČSN EN 61226 and is implemented on the SandRA platform with Z100 technical equipment. It is communicatively linked to the Unit Control and Information System (UCIS).

The Reactor Vessel Level Instrumentation System, supplied by ZAT a.s., currently ensures water level measurement in the reactor vessel and monitors the water level in VVER440-type reactors; however, we are ready to adapt the system based on requirements for other power levels and types of large and small reactors.

In-Core Measurement System

The system is designed for automatic centralized data collection and processing according to fixed algorithms. It processes real-time basic information about the status of the reactor core, primary circuit, and important parameters of the secondary circuit.

The IN-CORE system includes functions for collecting data from technological sensors (in-core neutron flux sensors, temperature sensors), data collection from other I\&C systems, input data processing (linearization, correction), performing calculations, data preparation and transfer to the supervisory system, and presentation on operator workstation screens. It performs safety functions in category C according to ČSN EN 61226 and is implemented on the SandRA platform using Z200 technical equipment. It is communicatively linked to the Unit Control and Information System (UCIS).

In addition to standard input signal diagnostics, the system also performs insulation diagnostics of sensors (conducted once a year during the fuel outage) and sensor vibration diagnostics. The in-core measurement system, supplied by ZAT a.s., currently ensures reliable and safe processing of information about the status of the reactor core, primary and secondary circuits of VVER440-type reactors, but we are ready to adapt the system based on requirements for other power levels and types of both large and small reactors.

Primary Circuit Technology Control

We offer the supply of a new or modernized system for controlling the primary circuit technologies of a nuclear unit (I\&C NO). The system complies with current legislative requirements regarding nuclear safety, operational reliability, operator and maintenance comfort, and meets strict qualification standards.

It provides control and information functions, enabling the collection of all operational and diagnostic data from connected measurement loops, actuators, and other devices. The system is implemented on the SandRA platform using Z100 and Z200 technical equipment. It performs safety functions in categories A, B, and C according to ČSN EN 61226. It is communicatively linked to the Unit Control and Information System (UCIS).

The system processes and verifies data, enabling online diagnostics and periodic functional testing of equipment.

Post-Accident Monitoring System

This system is a specialized, high-quality, and reliable display system designed to process and present parameters critical to the safety of the power plant, which operators need to use during accident conditions.

Primary functions include displaying parameters essential for post-accident monitoring. Specifically, it monitors critical safety functions of the plant as well as the integrity/breach of barriers against the release of fission products, confirms the functionality of safety systems, and enables operators in the control room to make all necessary safety-related decisions. It also confirms the safe shutdown of the reactor.

Secondary functions include providing information to determine the cause of the accident and supplying data to instruct other personnel to undertake specific and appropriate actions to ensure plant safety. The system performs safety functions in categories B and C according to ČSN EN 61226 and is implemented on the SandRA platform with Z100 technical equipment.

The Post-Accident Monitoring System (PAMS), supplied by ZAT a.s., ensures the processing and display of power plant parameters important for safety in VVER440-type reactors; however, we are prepared to adapt the system based on requirements for other power levels and types of large and small reactors.

Important references

-

Mrákov biogas station with Siemens control system

-

Central distribution control room for GasNet

-

Dispatcher control for LDS – Railway Administration

-

Central distribution control room for GasNet

-

Dispatch centers of the regional directorates of the Railway Association

-

Support for Ukrainian Healthcare

-

21st kindergarten Na Celchu

-

Hněvkovice hydroelectric structure

-

Reconstruction of the station building at Plzeň hl. n.

-

Reconstruction of the station building at České Budějovice hl. n.

-

Pakš Nuclear Power Plant

-

Research reactor and auxiliary technologies for the Institute of Nuclear Research "Řež"

-

Dukovany Nuclear Power Plant

-

Opatovice Power Plant

-

Power plant Felton, Cuba

-

Hydropower plant Gabčíkovo

-

Liptovská Mara pumped storage hydropower plant

-

Pilsen heating plant

-

Hydroelectric power plant Lipno I

-

Small hydropower plant Kořensko

-

Mělník I Power Plant

-

WWTP Mníšek pod Brdy

-

Management and analysis of cathodic protection - Pražská plynárenská

-

Emerson Climate Technologie

-

Denso manufacturing Czech s.r.o.

-

Project documentation for Štramberk UGS

-

Continental Automotive CZ

-

SAINT-GOBAIN, world leader in the building materials market

-

Life card

-

Modernisation of the biogas plant in Dobruška

-

Biogas station Bzovík

-

Starosedlský Hrádek biogas station with SandRA control system

-

Elementary school "Masarykova" in Klatovy

-

Alzheimer Center Roztoky

-

Telemetry stations for GasNet s.r.o.

-

Gas transfer station for the company EG.D

-

Emergency depressurization - UGS Štramberk

-

Landslide detection in Mosty u Jablunkova

-

Landslide detection in Karlovy Vary

-

Implementation of the I.P.P.E. Dýšiná technical control room

-

"Ejpovice" Tunnel

-

SimONet helps to save energy in the FC Viktoria Plzeň academy building

-

Gallery Klatovy / Klenová

-

Health center in pocket

-

Information system to support the sale of apartments, houses and plots

-

Health at the click

-

Electronics manufacturing for demanding industries

-

Production of the SandRA control system

-

Municipal water management Třeboň

-

Heating plant Náchod

-

Small incinerator Evecont - C-Energy Planá

-

Loviisa Nuclear Power Plant

-

Enguri Hydroelectric Power Plant

Excitation system replacement – TG2

Georgia, 2025

-

Repair of the signaling system in the Benešov nad Ploučnicí–Jedlová section

Implementation of the remote diagnostics system for technological systems

ČR, 2025

-

Reconstruction of the station building at České Budějovice Main Station

Implementation of the remote diagnostics system for technological systems

ČR, 2025

-

Hydroelectric Power Plant Štěchovice – TG3

Excitation migration of TG3

CZ, 2024

-

10 excitation units at hydroelectric power plants – Slovakia

Modernization of 10 excitation units

Slovakia, 2024

-

Kyzylorda Power Plant

Delivery of turbine turning synchronization

KAZ, 2024

-

Chvaletice Power Plant

Delivery of turbine turning synchronization

CZ, 2024

-

Golfech Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2024

-

Reconstruction of the station building at Plzeň Main Station

Implementation of the remote diagnostics system for technological systems

ČR, 2024

-

Reconstruction of the Teplice nad Metují railway facility

Implementation of the remote diagnostics system for technological systems

ČR, 2024

-

Reconstruction of the Janovice u Trutnova railway facility

Implementation of the remote diagnostics system for technological systems

ČR, 2024

-

Reconstruction of the neutral sections of the Planá u Mariánských Lázní and Mýto traction lines

Implementation of the dispatcher control technology system

ČR, 2024

-

Repair of the signaling system in the Běšiny–Nemilkov section

Implementation of the remote diagnostics system for technological systems

ČR, 2024

-

Gas transfer station Hospozín

Control system reconstruction

CZ, 2023

-

Opatovice Power Plant

Replacement of control system and field instrumentation - TG3

CZ, 2023

-

Plzeňská teplárenská - TGS

Delivery of turbine turning synchronization

CZ, 2023

-

Jafurah Cogeneration Power Plant

Delivery of turbine turning synchronization

SAE, 2023

-

Tanajib Cogeneration Power Plant

Delivery of 2 turbine turning synchronization systems

SAE, 2023

-

Temane Thermal Power Plant

Delivery of turbine turning synchronization

Mozambik, 2023

-

Olefin chemical plant

Delivery of 2 turbine turning synchronization systems

Polsko, 2023

-

Reconstruction of the platforms at Semily Railway Station

Implementation of the remote diagnostics system for technological systems and dispatcher control technology

ČR, 2023

-

Reconstruction of the interlocking system at Kopidlno Railway Station

Implementation of the remote diagnostics system for technological systems

ČR, 2023

-

Repair of dispatcher control technology at J. Hradec and Počátky-Žirovnice Stations, and J. Hradec SCF

Implementation of the dispatcher control technology system

ČR, 2023

-

Reconstruction of the station building at České Budějovice Main Station

Implementation of the dispatcher control technology system

ČR, 2023

-

Reconstruction of Bohosudov Railway Station

Implementation of the remote diagnostics system and dispatcher control technology

ČR, 2023

-

ETCS and DOZ implementation on the Votice–České Budějovice section

Implementation of the remote diagnostics system and dispatcher control technology

ČR, 2023

-

Waterworks Lipno

Modernization of the control system on the SandRA platform

CZ, 2022

-

Custom production

Production of 140 pieces of a medical device for a customer

CZ, 2022

-

Gas transfer control station Makotřasy

Control system reconstruction

CZ, 2022

-

Slough waste incineration plant

Delivery of turbine turning synchronization

Velká Británie, 2022

-

Belleville Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2022

-

Revitalization of the Lovosice–Česká Lípa railway line

Implementation of the remote diagnostics system for technological systems

ČR, 2022

-

Transfer control station Krupá

Control system and boiler room reconstruction

CZ, 2021

-

Cathodic protection station Skalice nad Svitavou

Wireless measurement from cathodic protectors

CZ, 2021

-

Heating plant Příbram

Reconstruction of the boiler control system due to transition to another fuel

CZ, 2021

-

Heating plant in Tabor

Migration of the boiler control system in connection with fuel change

CZ, 2021

-

Biogas station Dlouhá Lhota

Supply of control system and monitoring system with Simatic S7-300 PLC and Reliance visualization

Czech Republic, 2021

-

WWTP Tuchlovice

Delivery of Schneider control and monitoring system

CZ, 2021

-

Coal preparation Ledvice

Delivery of Siemens S7 1500 control system for coal conveyor belt control

CZ, 2021

-

Waterworks Žilina

Reconstruction of excitation controllers TG1 and TG2

SK, 2021

-

Railway line Oldřichov u Duchcov - Bílina

Implementation of Remote Diagnostics and Technological Systems

CZ, 2021

-

Railway station Strakonice

Addition of Remote Diagnostics of Technological Systems

CZ, 2021

-

Dubai waste incineration plant

Delivery of turbine turning synchronization

SAE, 2021

-

Lostock waste incineration plant

Delivery of turbine turning synchronization

Velká Británie, 2021

-

Kemi waste incineration plant

Delivery of turbine turning synchronization

Finsko, 2021

-

Transfer station Libenice

Control system and boiler room reconstruction

CZ, 2020

-

Railway station Jaroměř

Reconstruction and implementation of Remote diagnostics of technological systems

CZ, 2020

-

Plzeň junction, 3rd construction - Domažlice railway crossing

Implementation of Dispatching Control Technology

CZ, 2020

-

Underground storage tank Štramberk

Reconstruction of the compressor station control system

CZ, 2020

-

Nogent-Sur Seine Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2020

-

Compression station Veselí nad Lužnicí

Control system of the pipe yard

CZ, 2019

-

Distribution node Rozvadov

Control system reconstruction

CZ, 2019

-

Empalme Thermal Power Plant I,II

Delivery of 2 pieces of excitation generators 300 MW

Mexico, 2019

-

Acerra incinerator

Upgrade of steam turbine control system from Simatic - Simadyn instrumentation to Simatic S7-400 instrumentation

Italy, 2019

-

Temelín Nuclear Power Plant

Reconstruction of the I&C wastewater treatment plant, project B607

CZ, 2019

-

Metsamor Nuclear Power Plant

Unit 2 - control system for group and individual control of VVER 440 nuclear reactor rods

Armenia, 2019

-

Railway line Týniště nad Orlicí - Broumov

Implementation of Dispatcher Control Technology and Remote Diagnostics of Technological Systems

CZ, 2019

-

Penly Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2019

-

Grati Thermal Power Plant

Delivery of the steam turbine control and protection system, field instrumentation, and cabling

Indonesia, 2019

-

Škoda Auto

Support for shop floor management through visualisation of production data on electronic boards

CZ, 2018

-

Underground storage tank Štramberk

Reconstruction of the control system of the drying and regeneration section

CZ, 2018

-

Mochovce Nuclear Power Plant

Replacement of the Group and Individual Control System for Reactor Control Mechanisms (RRCS), Unit No. 1 and No. 2

Slovakia, 2018

-

Health +

Making pharmacy report data, test results and recommended medications available to patients

ČR, 2017

-

Heating plant Katowice

Reconstruction of turbine control system, reconstruction of 120 MW generator excitation

Poland, 2017

-

Waterworks Kořensko

Modernization of the control system on the SandRA platform

CZ, 2017

-

Jirkal Komaxit

Replacement of the existing relay control of the spray line with the modern ZAT SandRA Z210 series control system

CZ, 2017

-

Flamanville Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2017

-

CEPS

Specialized system providing advanced process support across the company CEPS

Czech Republic, 2016

-

Heating plant Písek

Reconstruction of electrostatic precipitator source control - boilers K11 and K12

CZ, 2016

-

Lisbjerg Incinerator

Delivery of the steam turbine control system, related field instrumentation, and cabling

Denmark, 2016

-

Thermal Power Plant Morupule

Delivery of synchronization of turbine rotating equipment

Botswana, 2016

-

Hanhikivi Nuclear Power Plant

Implementation of part of the conceptual project of the Group Control System, Unit 1

Finland, 2016

-

Cattenom Nuclear Power Plant

Delivery of KCF system (4x PWR 1330)

France, 2016

-

Saint-Alban Nuclear Power Plant

Delivery of KCF system (2x PWR 1330)

France, 2016

-

Jaslovské Bohunice Nuclear Power Plant

Replacement of the Group and Individual Control System for Reactor Control Mechanisms (RRCS), Units 3 and 4

Slovakia, 2016

-

Small hydroelectric power plant Střekov

Modernization of excitation regulators TG1 to TG3

CZ, 2016

-

HEC Services

Intelligent system for automatic collection, processing and application of data on electricity supply and consumption

CZ, 2015

-

Thermal Power Plant Gardabani

Supply of steam turbine control and protection system, field instrumentation and cabling

Georgia, 2015

-

Paluel Nuclear Power Plant

Delivery of KCF system (4 x PWR 1330)

France, 2015

-

School reactor CTU, FJFI Prague

VR-1 school training reactor information system including web services

CZ, 2015

-

Biogas station Slatina

Supply of control system and monitoring system, including connection to heat conductor

Czech Republic, 2014

-

CZ LOKO

System for financial management, budgeting, controlling and forecasting

Czech Republic, 2014

-

Emerson Climate Technologies

Custom information system for collaboration between engineering and test lab

CZ, 2014

-

Heating plant Strakonice

K2 boiler control, new application software including visualization

CZ, 2014

-

Trams in Turkey

Air conditioning inverters for trams Konya Turkey

Turkey, 2014

-

Biogas station Stanoviště

Supply of control system and monitoring system

Czech Republic, 2013

-

Heating plant Dvůr Králové

Delivery of SW works of acoustic cleaners of K2 output superheater

CZ, 2013

-

Zellstoff Stendal GmbH Incinerator

Delivery of the steam turbine control system, related field instrumentation, and cabling

Germany, 2013

-

Biogas station Mýšlovice

Supply of control system and monitoring system

Czech Republic, 2012

-

Biogas station Dvorianky

Supply of control system and monitoring system

Slovakia, 2012

-

Thermal Power Plant Vojany

Reconstruction of turbine controller B16

SK, 2012

-

Biogas station Smolotely

Supply of control system and monitoring system with Simatic S7-300 PLC and Reliance visualisation

Czech Republic, 2012

-

Thermal Power Plant Talkha

Replacement of generator excitation, reconstruction of turbine control system

Egypt, 2011

-

CBRE Global Investors Central Europe

Applications for commercial buildings supporting the budget-making processes and their approval

Europe, 2009

-

Čepro

Extranet solution for recording, processing and analysis of corrosion cathodic protection data

CZ, 2007

-

Innogy

Extranet solution for recording, processing and analysis of corrosion cathodic protection data

CZ, 2007

-

Mero

Extranet solution for recording, processing and analysis of corrosion cathodic protection data

CZ, 2007

-

South Ukrainian Nuclear Power Plant

Control system for group and individual control of nuclear reactor rods VVER 1000, Units 2 and 3

Ukraine, 2005

-

Chmelnicka Nuclear Power Plant

Control system for group and individual rod control of VVER 1000 nuclear reactor, unit 2.

Ukraine, 2004

-

Rovenská Nuclear Power Plant

Control system for group and individual control of control units/rods of VVER 1000 nuclear reactor, unit 4.

Ukraine, 2004

-

Zaporozhye Nuclear Power Plant

Control system for group and individual control of the rods of the VVER 1000 nuclear reactor, Units 3 and 4.

Ukraine, 2004

-

Compass Group

Collection and processing of accounting data in a distributed branch accounting system

Czech Republic, 2000

Want to know more? Contact us!

Karel Stočes

Guarantor of nuclear power sector

karel.stoces@zat.cz

+420 736 519 306